Semiramis is instaled

13. Jun 2022

In the Tech Cluster Zug, the sculpture Semiramis was recently instaled, symbolizing the connection between high-tech and nature. TS3 and Timbatec made a significant contribution to the fact that the complex wooden shells now seem to float weightlessly at an airy height.

For the Tech Cluster Zug, researchers from the group of ETH architecture professors Fabio Gramazio and Matthias Kohler built a planted architectural sculpture together with Müller Illien landscape architects, TS3 and other partners. The 22.5-meter-high structure consists of five geometrically complex wooden shells that are supported - slightly offset from each other - by eight slender steel columns. Last week, the erection ceremony was celebrated with all those involved.

Joint grouting without pressure

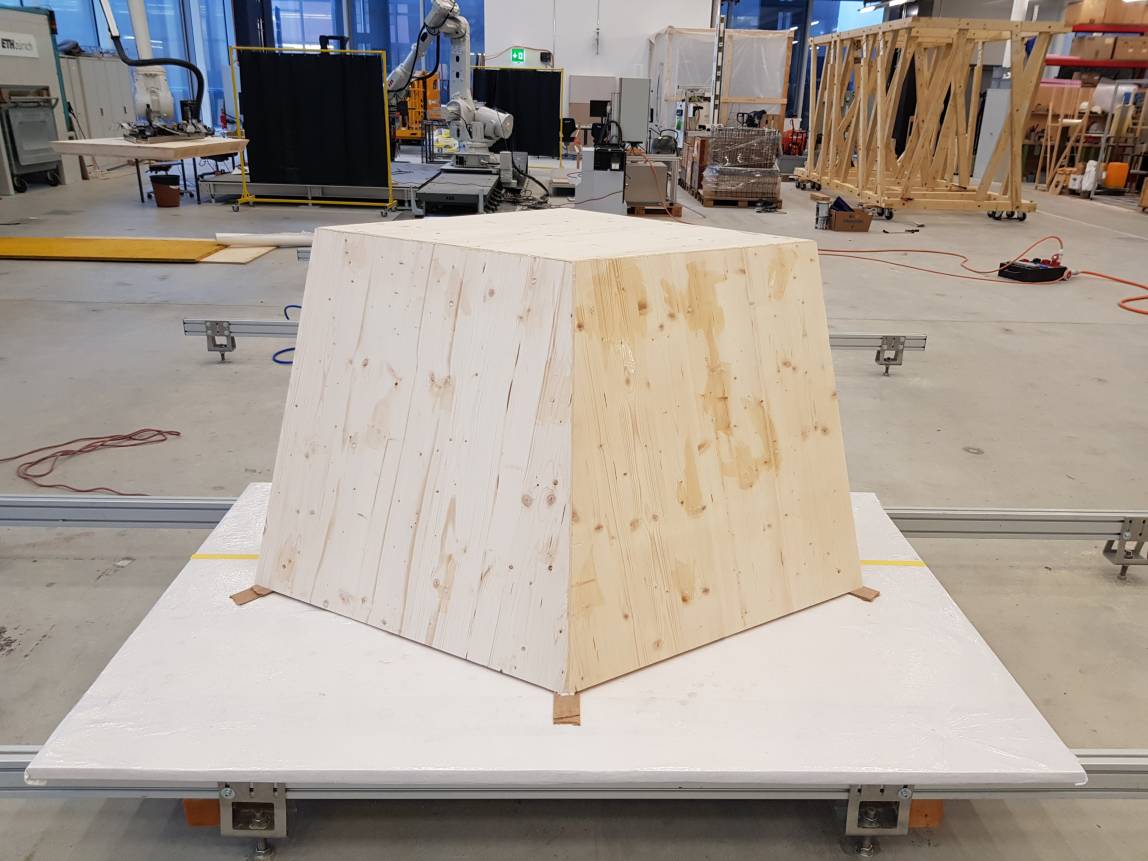

Always in sync, four suspended robot arms pick up the wooden panel assigned to them, perform a high-precision dance and finally place the panels in space according to the computer design. An algorithm calculates the robots' movements in such a way that no collisions occur. Once the machines have placed their four panels next to each other, they are first temporarily joined by craftsmen and then bonded together with a TS3 casting resin. In this way, the cross-laminated timber panels can be joined to each other on the face side by joint grouting without applying pressure. The TS3 system is mainly used for the construction of floor slabs, but also allows structures such as semiramis. Thus, between 51 and 88 such wood panels are joined to form a wooden shell.

In contrast to traditional timber construction, robotic manufacturing has several advantages: On the one hand, the robots relieve humans of the heavy lifting and exact positioning, and on the other hand, costly, resource-intensive substructures can be dispensed with in the assembly process.

A symbol of cooperation

Robotic prefabrication is currently running at full speed. The individual shell segments have been continuously transferred to Zug on trucks and the architectural sculpture will then be erected and finally planted in spring 2022. From summer 2022, it will be possible to view the wooden structure from the ground and buildings and catch a glimpse of the greened shells. The slender and tall structure will be lushly planted with large shrubs and trees, giving it a stately weight of its own. At the same time, it represents a large attack surface for the wind. Thanks to the advantageous round shape of the shells, it is guided around the structure. Nevertheless, the stiffening of the structure with its eight slender columns is a challenge. The wind pressures on the shell were calculated with a fluid mechanical RWIND simulation from Dlubal Software, which simulates the flow around the structure in a wind tunnel. In addition, due to the slender construction, resonance effects along and across the wind direction had to be considered in the calculations.

In the classic design process, architects try to take into account the different requirements of a building or structure in the design and then adjust it until all of them are met as well as possible. Not so with Semiramis: a customized machine learning algorithm, developed in collaboration with the Swiss Data Science Center, showed the researchers sophisticated design options. The proposals differed in terms of the shapes of the trays and their spatial arrangement relative to each other, but also showed how each design affected individual target variables, such as irrigation of the trays. "The computer model allows us to reverse the conventional design process and explore the full design scope for a project. This results in new, often surprising geometries," says Matthias Kohler, professor of architecture and digital fabrication at ETH Zurich.

In the "Immersive Design Lab," an augmented reality laboratory on the Hönggerberg campus, the researchers were able to explore the designs in three dimensions and continue working on them together in real time. Software developed jointly with ETH's Computational Robotics Lab also allows them to easily adjust the designs of the wooden shells: For example, if the scientists move a single point within the geometry of one of the shells, which are composed of around 70 wooden panels, the software adjusts the entire geometry. At the same time, it takes into account the relevant manufacturing parameters, such as the maximum possible weight of a panel, and thus always generates the most efficient and resilient configuration.

ETH develops a plant tower with artificial intelligence

Neue Zürcher Zeitung, Ausgabe 24.11.2021 – Zu den sieben Weltwundern der Antike gehören die Hängenden Gärten der babylonischen Königin Semiramis. «Semiramis» heisst eine 22,5 Meter hohe architektonische Skulptur mit 100 einheimischen Pflanzenarten. Forschende aus der Gruppe der ETH-Architekturprofessoren Fabio Gramazio und Matthias Kohler haben das Pflanzen-Hochhaus mit einem Machine-Learning-Algorithmus entwickelt.

Robots are building new hanging gardens

Baublatt, Ausgabe Nr. 2/2022 – Computermodelle erschliessen neue Gestaltungsspielräume mit oft überraschenden Geometrien. Mit Hilfe künstlicher Intelligenz und kooperierenden Robotern entstehen im Fertigungslabor der ETH Zürich die Bauteile für eine bepflanzte architektonische Skulptur.

Semiramis Robotics Project: Hanging Gardens for Zug

Wir Holzbauer, Ausgabe 1.2022 – Als Weltwunder sind die hängenden Gärten der Semiramis von Babylon bekannt. Die neuen schwebenden Gärten auf dem Areal des Tech Cluster Zug sollen zumindest schweizweit für Aufmerksamkeit sorgen. Ende November wurde das Robotikprojekt «Semiramis» an der ETH Zürich vorgestellt.

Semiramis – the hanging gardens of Zug

Semiramis News by TCZ, 1/2022 – In Zug entsteht an der Ecke Ahornstrasse/Industriestrasse ein ganz besonderes Kunstwerk. In Anlehnung an die berühmten hängenden Gärten im alten Babylon heisst die elegante Konstruktion Semiramis. In fünf frei geformten und raffiniert angeordneten Holzschalen werden Gräser, Blumen, Stauden und Sträucher wachsen, ja sogar Bäume. Das Kunstwerk aus Hightech und Natur soll die Mitte des neuen Tech Cluster Quartiers markieren.

Involved

Design

- Matthias Kohler, Professor of Architecture and Digital Fabrication

- ETH Zurich

- Rita Illien, Müller Illien Landscape Architects

- Andreas Burgherr, Timbatec Holzbauingenieure

Planning and execution

- Team Gramazio Kohler Research

- Total contractor Erne AG Holzbau with:

Subplanner:

- Timbatec Holzbauingenieure

- MWV Bauingenieure

- Dr. von Moos AG, Geologie

- LLAL AG, Lichtplaner

- Bänziger Partner AG, Planung Bach

Subcontractors:

Landis Bau - master builder, Go Bau AG - construction management Bach, JMS RISI AG - civil engineering, Smarterion - lighting engineering, Zumtobel AG - lighting, Hotz Elektro AG, Forster Baugrün - gardening, Roth - scaffolding, Abt Holzbau AG - assembly, TS3 Timber Structures 3.0 AG - bonding, Josef Meyer - Stahl und Metall AG, Schilliger Holz AG