Showcase wood construction with TS3 technology

08. Feb 2022

The Generation House W52 with GEAK-A energy label actively promotes communal and intergenerational living. An ecological and energy-optimized construction method with wood was required from the very beginning.

The replacement building at Wehntalerstrasse 52 in Zurich-Unterstrass has been occupied. With the use of TS3 technology, clay panels, sheep's wool insulation and flexible walls, timber construction is highly interesting from an ecological and technical point of view.

Floor slabs with TS3 technology

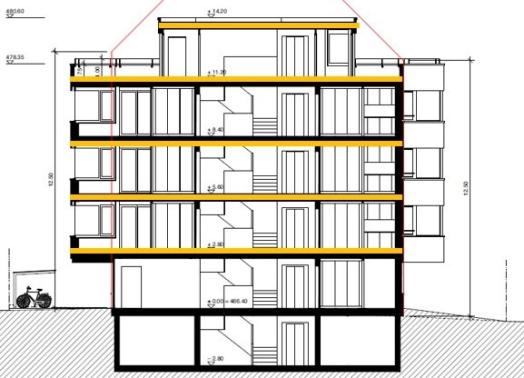

The building typology was ideally suited for TS3 technology. The cross-laminated timber panels for the floor slabs of the five-story wooden building were pre-treated with a primer at the Schilliger company's manufacturing plant. On site, these panels were joined together face-to-face by a TS3 application technician using joint grouting and no pressing pressure. This creates large areas of wood and the forces can be transferred at defined points into the exterior walls and into the concrete stairwell. This allows the formation of non-load-bearing interior walls with the aforementioned flexibility.

Thanks to the biaxial load-bearing timber ceilings, the cantilevered balconies and bay windows on all sides could be efficiently and easily constructed in pure timber. The ceilings span around the concrete staircase core to the exterior walls, so that no load-bearing components are required inside the building. The interior walls, as well as the building services, were designed so that individual rooms can be easily swapped between apartments.

Thermal bridges made simple. Because of the low thermal conductivity of wood, there is no need for elaborate cantilever connections. The CLT ceiling simply runs from the apartment to the loggia.

Focus on building physics

Well thought-out concepts for building acoustics and noise protection are in demand. Timbatec Holzbauingenieur Schweiz AG develops these with foresight, thus ensuring noise protection and pleasant room acoustics, especially in the area of co-working spaces. An ecological construction method also requires the careful selection of building materials: The use of wood, clay and sheep's wool is a good example of modern yet considerate construction.

A 6 cm thick Fermacell honeycomb fill over the cross-laminated timber ceilings, combined with the mineral impact sound insulation and the subfloor, ensures compliance with the requirements regarding airborne sound and impact sound. The floor slab also makes an important contribution to thermal insulation in summer.

Ceilings made of CLT panels grouted with TS3 technology, with fill, impact sound insulation and underlayment floor

Timbatec consistently refrains from using wood-concrete composite floors due to ecological considerations. With the above, resource-saving floor structure, in conjunction with quality assurance at the construction site, the sound insulation requirements can be met. In projects with property standards, the floor construction is adapted to the requirements accordingly.

Flexible partition walls

Timbatec developed three variants for the non-load-bearing interior walls. The Basic variant is used inside the apartments. Thanks to doubling on both sides, it can be used as an apartment partition wall. Where necessary, the walls are replaced by door sills. The result is a highly flexible building with apartment sizes that can be adapted to current needs.

Connection apartment partition wall to ceiling. These were planned so that they can be converted into an internal room partition without major intervention

From the inside, the wood remains visible and gives a pleasant atmosphere.

Cross-section of the MFH at Wehntalerstrasse 52. The ceilings with TS3 technology are marked in yellow.