TS3 endurance test bench dismantled

21. Jun 2021

The TS3 long-term test bench at the Bern University of Applied Sciences delivered important results for the successful development of TS3 technology and helped the technology achieve its market breakthrough. It has now been dismantled. In the spirit of the circular economy, a new object is being created from the cross laminated timber panels: two box girder elements for heavy-duty bridges.

The new TS3 technology enables large wooden surfaces. Ten years of research together with the Bern University of Applied Sciences and ETH Zurich were necessary to develop the technology. An important milestone was the long-term test stand in the inner courtyard of the Bern University of Applied Sciences in Biel. It has served well and has now been dismantled.

Would you like to load this additional content?

This placeholder hides an external resource that has not been loaded due to your cookie settings.Click on the button below to allow this resource.

Successful market launch for TS3 technology

The long-term test stand was officially inaugurated on May 16, 2018. In the same year, construction work began on the world's first apartment buildings with TS3 technology in Grossaffoltern (BE). Since then, 15 projects with an area of around 6,000 square meters have been completed - not only in Switzerland, but also in Austria, Canada and the USA. These include flagship projects such as the world's largest continuous cross-laminated timber panel as the flat roof of the new Handl production building in Tyrol, Austria. Or the Fasanenhof apartment building in Frenkendorf, which is currently being completed with a total of 15 apartments. A further 10,000 square meters will be added this year. You can find an overview of the completed projectshere.

Further research and development work is needed to ensure that TS3 construction projects can be built even more efficiently and cost-effectively and that the technology successfully establishes itself on the market.

Further research projects

The CTI research project Timber Structures 3.0 technology, which included the long-term test bench, was successfully completed at the end of June 2020. Information on the research project can be found on the website of the BFH.

As a follow-up project, the Innosuisse research project "Achieving market maturity of the biaxial load-bearing flat slab system in timber construction" started on 01.01.2021. Over the next three years, TS3 will be researching and optimizing the TS3 system together with Henkel & Cie AG and Schilliger Holz AG as well as the research partners ETH Zurich and Bern University of Applied Sciences. Innosuisse is supporting the research institutes with around CHF 700,000. The implementation partners will provide the same amount again.

Two work packages are being carried out at the Bern University of Applied Sciences. On the one hand, the Institute of Timber Construction, Structures and Architecture IHTA is optimizing the suitability of TS3 for construction sites under the title "Pour to solid (PTS) to market" under the leadership of Prof. Dr. Steffen Franke. On the other hand, the industrialization of the technology is being further developed by Prof. Dr. Klaus Rehm at the Institute for Digital Construction and Timber Industry IdBH. At the ETH, Prof. Dr. Ingo Burgert's Institute for Building Materials is researching the interaction of the wood-adhesive system and Prof. Dr. Andrea Frangi's Institute for Structural Analysis and Design is developing a biaxial load-bearing box girder floor that will be integrated into the TS3 system. Together, the work packages will lead to an increase in load-bearing capacity, an expansion of the area of application and ultimately also to an increase in efficiency in the use of the TS3 connection.

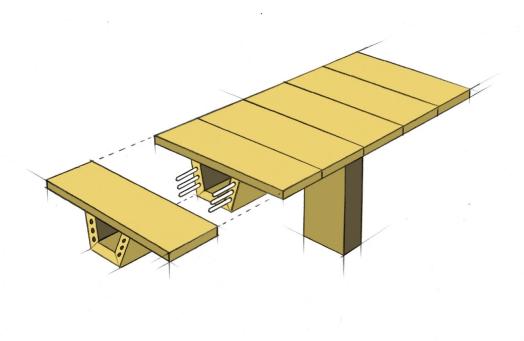

New object from old panels

In the spirit of the circular economy, the cross-laminated timber panels from the long-term test bench, which has been in place at BFH in Biel since 2018, will be reused for an initial exhibition object. Two box girder elements of a two-lane road bridge on a scale of 1:1 will be created from the panels from the test stand. The elements show parts of a road bridge transverse to the axis, which could, for example, lead over a four-lane highway. Prestressing in the webs of the box girder enables the large spans to withstand high loads from road traffic. The bridge will be inaugurated at the 4th International Conference on Timber Bridges in spring 2022.