TS3 is the solution for large-scale timber construction and column spacing of up to eight by eight meters. This makes large buildings and exceptional timber architecture possible.

Planning with FEM software

TS3 structures are best planned with FEM software. Currently the company Timbatec is your contact. In the future, other engineering companies will also offer these services. We train interested companies and persons by means of e-learning.

New column head for large spans

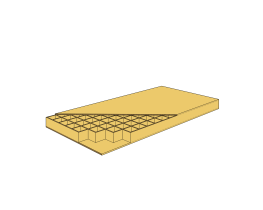

To transfer the large floor slab loads to the columns, TS3 has developed a specially layered column head element. In tests, the technology has achieved failure loads of 1,100 to 3,100 kN (110 to 310 tons), depending on the slab thickness and structure.

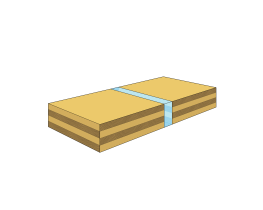

Joining panels at the edges

The key technology of TS3 is the TS3 connection by edge joint grouting at a distance, without pressing and without any other connecting means. This allows panels of any size to be produced. After ten years of research more than 2,000 tensile and bending tests, the technology is ready.

Quality assurance processes

TS3 has developed a system for quality assurance. It ensures that the load-bearing safety and serviceability of TS3 connections is guaranteed and traceable at all times.

Planning with FEM software

TS3 structures are best planned with FEM software. Currently the company Timbatec is your contact. In the future, other engineering companies will also offer these services. We train interested companies and persons by means of e-learning.

New column head for large spans

To transfer the large floor slab loads to the columns, TS3 has developed a specially layered column head element. In tests, the technology has achieved failure loads of 1,100 to 3,100 kN (110 to 310 tons), depending on the slab thickness and structure.

Joining panels at the edges

The key technology of TS3 is the TS3 connection by edge joint grouting at a distance, without pressing and without any other connecting means. This allows panels of any size to be produced. After ten years of research more than 2,000 tensile and bending tests, the technology is ready.

Quality assurance processes

TS3 has developed a system for quality assurance. It ensures that the load-bearing safety and serviceability of TS3 connections is guaranteed and traceable at all times.

Advantages

TS3 can do everything concrete can do.

And much more.

Tall and large buildings made of wood

The large column grid makes TS3 a real alternative to concrete - for housing estates, industry, hospitals, schools and administrative buildings.

Flexibility of use

Structural changes are easier to implement than with concrete or conventional timber constructions. Your building therefore remains highly flexible over its entire service life.

Climate-friendly and local

Wood stores CO₂ and TS3 is also many times more environmentally friendly than concrete in production. The raw material grows in the region, and transport distances are short.

Building speed

Timber buildings do not require a drying-out period, as is common with concrete buildings. The projects are thus ready for occupancy much more quickly and yield a faster return than projects in conventional construction methods.

8 x 8 meter column grid

Until now, timber construction has been single-axis load-bearing and dependent on beams. With TS3, floor slabs distribute loads in two directions and span columns in a grid of8x8meters.

Lightweight and space saving construction

TS3 floor slabs are space-saving in thickness - a planning advantage. In addition, TS3 is lightweight, making it perfect for additions.

High quality of living

Wood has unique properties for a pleasant indoor climate: it breathes, feels warm and creates comfortable spaces for various uses.

Freeforms

Anyone looking for design freedom is on the right track with TS3. It opens up completely new architectural possibilities.

Process

Easy process for large projects

TS3 does not challenge you, on the contrary: it makes design, planning, transport and processing easy.

Generations

The 3rd generation in timber construction technology

Timber Structures 1.0- the origin of timber construction

Felling trees, removing branches, debarking them, sawing them into beams if necessary, and erecting buildings. That was the first generation of timber construction.

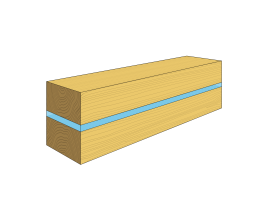

Timber Structures 2.0 - the familiar technology

Since the 20th century, trees have been sawn into boards, dried, planed and glued into glulam. This allows beams to be created that are longer than trees are tall. Beams transfer the loads to the supports.

Timber Structures 3.0 - Timber becomes better than concrete

The TS3 technology connects timber components on the edge. This makes it possible to produce panels of any size. Beams are no longer necessary thanks to high-tech column heads. Timber construction is thus conquering the spheres of conventional concrete construction.

Research

We continue to research

TS3 emerged as a startup from the Timbagroup. There is still a lot of potential in timber construction. This is why we continue to research and found further startups when promising ideas arise. Our current projects in the Timbagroup:

To make the TS3 technology even lighter, the ETH and the Bern University of Applied Sciences are developing a biaxial load-bearing filler element in the form of a GridBox (hollow box with girder grid interior).

The construction industry has a duty and must significantly reduce its CO₂ emissions in order to comply with the Paris climate agreement. This can only be achieved by dispensing with steel and concrete in building construction. The next logical step is to do away with concrete in basements and floor slabs.

With scrimber technology, timber logs are no longer sawn in a sawmill, but are shredded into long strands with large drums, dried, and then pressed into rectangular pieces. This is a very efficient process for producing load-bearing components for long-term carbon storage.

FAQ

The most important questions

Do you have further questions? Get in touch with us.

- Which are the advantages of timber buildings in general?Timber construction is experiencing a real boom in Europe. Apartment buildings with over 300 apartments, commercial and industrial buildings, administrative buildings, hotels and high-rise buildings made of wood bear witness to this. The most important advantages of timber construction compared to other construction methods are the faster construction time and the resource- and climate-friendly use of building materials, since wood is a renewable raw material. Here you will find a compilation of the most important advantages of timber construction.

- Which are the advantages of TS3 over concrete?Thanks to TS3, wood can do everything that concrete can. Simple, sustainable and ecological. Buildings with steel and concrete cause very high CO₂ emissions during production. Cement production alone is responsible for five to eight percent of global CO₂ emissions. One cubic meter of reinforced concrete causes around 500 kg of CO₂ emissions during its production. The situation is quite different with wood: The naturally renewable building material requires only solar energy and water for its production. As it grows, a tree converts CO₂ into oxygen thanks to photosynthesis. Each cubic meter of wood thus stores around one ton of CO₂ in the long term. Anyone who wants to make a contribution to climate protection is building with wood today.

- What material is the joint of the TS3 joint made of?The TS3 compound consists of a two-component polyurethane casting resin made partly from biobased materials. The organic matrix of the mixed polyurethane casting resin has a biobased content of about 50%, which comes from renewable raw materials such as vegetable oils and their derivatives. The raw materials used comply with the legal requirements of the European Union (EU) and REACH. The casting resin used in TS3 technology does not contain any chemicals on the Substance of very high concern (SVHC) list and therefore does not pose a risk to human health or the environment. For more information on the casting resin, please refer to the factsheet.

Newsletter

Stay informed

Subscribe to our newsletter now - for TS3 updates and selected input on innovations in the construction industry.